How the AR-15 Direct Impingement gas system works

Originally posted on AR15.com on 1-24-06:

I wrote this the other night in response to a forum post, but I think it's good enough to have it's own page. This is just off the top of my head. Much of it comes from Rick McDowel (competetion specialties) when I was first learning AR's & from Tweak (on AR15.com) along the way and my own experiences mixed in along the path to enlightenment on how everything works in harmony.

Ok, starting with a cartridge in the chamber, hammer back.

Trigger lets the hammer fall.

Hammer hits the firing pin, driving it forward.

Firing pin drives the primer (and attached cartridge case) forwards in the chamber until the shoulder in the chamber stops the shoulder on the cartridge case.

The case will already be seated against the shoulder due to ejector tension, but the primer can sometimes move before the anvil legs on the primer stop against the primer pocket.

Headspace is the distance from the bolt face to the head of the cartridge when fully seated in the chamber.

Headspace gauges account for the length of the cartridge AND for the recommended amount of headspace, but what really matters is the amount of space, or lack there-of, of space between the case head and bolt face.

You need some headspace or there will not be enough room for the bolt lugs to lock into engagement if you get any dirt or drit on your ammo. You don't want too much space though or you run into problems with brass stretching or ignition problems and case failures in extreme cases.

The firing pin continues forward to ignite the primer.

Primer flash ignites powder charge, instantly creating great pressure within the cartridge case.

Cartridge case expands first outward towards chamber walls (path of least resistance) where pressure holds the case in place and then the case stretches backward until the case head is stopped against the bolt face.

That is WHY long headspace makes cases fail!

It's normal for the brass to stretch rearward a couple thousandths and the brass will spring back when chamber pressure subsides. You don't want to have enough headspace for the brass to yield (permanently stretch) as the case gets thin just above the extraction groove where the walls thin out. Excessive headspace shows up on the cases as a shiney ring about 1/8" forward of the extraction groove.

Bullet begins movement down the barrel, first encountering the throat.

Here is why you want a throat DIAMETER closely matching the bullet.

Loose throats do not control the bullet and keep it as straight while engraving into the rifling.

More about throat dimensions can be found here.

As the bullet starts down the barrel, it jams into the rifling where pressure causes the rifling lands to "engrave" into the bullet. Dependng on the aspect ratio of the lands to grooves, the bullet will sometimes grow in length. This radical change in bullet shape can often be detrimental to accuracy.

Ideally, you would want a barrel with an odd number of lands and grooves.

This allows the bullet to obturate more gently.

Now the bullet has obturated and engraved into the rifling and it's accelerating rapidly down the bore.

As it passes the gas port, gas begins to flow into the gas block where it turns and heads towards the bolt carrier via the gas tube.

The pressure is still high in the barrel, usually 15,00PSI+ until the bullet leaves the muzzle.

Just as the bullet leaves the muzzle, gas escapes around the base of the bullet.

Here is why a proper crown is important.

Gas is traveling about 5x faster than the bullet when it leaves the muzzle.

An even crown releases gas all the way around the bullet at one time.

An un-even crown lets gas go on one side first.

This can tip the bullet just slightly sideways at the moment the bullet is released into the air.

This is a very important time in the bullet's flight.

Now, remember, high pressure gas always follows the path of least resistance, which is now out the front of the barrel instead of into the gas system.

Barrel pressure drops immediatly.

During the bullet's travel down the bore between the gas port and the muzzle, we had a metered amount of gas fed to the action.

This gas does the following:

Upon reaching the gas key bolted to the top of the carrier, it turns down into the bolt carrier where it is given a nice place to expand.

This is the area inside the bolt carrier where the bolt lives.

Gas expanding here forces the bolt carrier back AND the bolt forward.

Note that the bolt is also being forced BACK by the gas pressure expanding the cartridge case on the other side of the bolt.

For a short moment in time, these forces are about equal.

Ideally, this is while the bolt lugs are unlocking and before the extractor starts pulling on the case.

The bolt carrier starts to move backwards against the inertia of the carrier's weight, the buffer's weight and the operating spring.

All of these effect timing, that's why we have different weights of buffers; standard, heavy (H), H2, H3 etc.

The next thing the carrier encounters are the cam surfaces against the cam pin.

Of course we know that the cam pin goes through the bolt.

Rearward movement of the bolt carrier causes the bolt to rotate.

(pay attention here, this is the meaty part)

Here is where timing comes into play.

Let's make a couple assumptions here before we continue.

Trust me that pressures in the case hold the case into the chamber, even though the chamber is slightly tapered.

Also trust me that when you release all the pressure out the front of the barrel that the cartridge case will spring back down to size so it's no longer a tight fit in the chamber as it was with the gas pressure present.

So here's where timing comes into play.

We want the bullet to be out of the front of the barrel AND the pressure to have subsided enough that the case shrinks down BEFORE the bolt lugs are unlocked because when the pressure is high, the case WILL try to stay in the chamber.

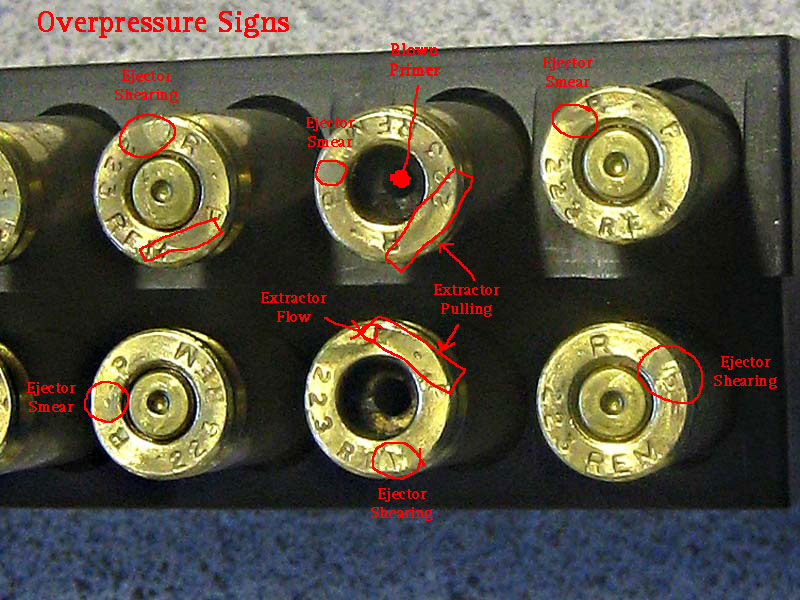

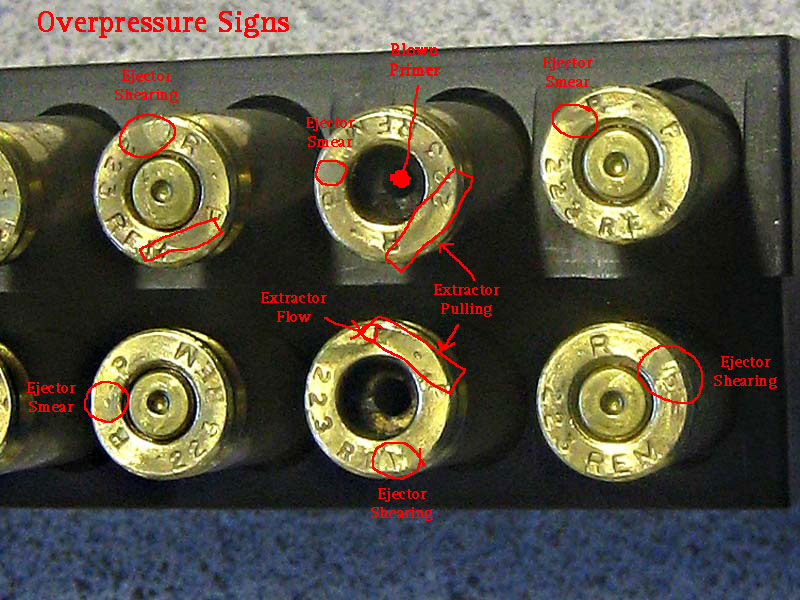

Now is the perfect time to point out that one sure sign of high pressures are the fact that the case extrudes into the ejector plunger hole on the bolt and the resulting pressure unlocks the bolt while pressures are still high.

This extruded brass gets wiped off the end of the case head, leaving a shiney spot and the brass usually makes it's way under the extractor, later causing extraction problems we will get to in a little bit.

Here is a graphic illustrating what happens when pressures are too high and the gas system is getting too much gas:

Now back to extraction, normal/correct version:

Pressure subsides, bolt unlocks, carrier momentum continues rearward, pulling the fired (and contracted) cartridge case from the chamber.

As the cartridge case reaches the ejection port, the case pivots on the extractor hook from pressure of the ejector until it is sent flying free of the rifle.

The bolt carrier continues backward while re-cocking the hammer until operating spring pressure or the buffer stops it.

Operating spring (buffer spring) returns the bolt carrier forward where it strips another round from the magazine up the feedramps and into the chamber.

Cartridge stops in the chamber, bolt continues forward, causing the extractor to snap over the rim of the cartridge case.

Bolt finally stops against the case head, but the carrier continues forward.

The cam surfaces in the carrier now cause the bolt to lock into battery again.

Now we are back where we started before we ever pulled the trigger.

Now for extraction, the WRONG ways.

First, too much gas(most common):

The bullet has not left the barrel yet, but it's past the gas port.

Too much high pressure gas is rushing into the carrier, causing it to move rearward faster then desired and unlock the bolt from the extension.

Pressures are still high so the cartridge case is NOT ready to be extracted yet.

The carrier's momentum continues to pull backward, but the pressures in the case actually hold in in the chamber.

This causes a hiccup in the carrier's momentum.

Depending on the severity of the timing, several things can occur:

#1 The (weak) extractor spring allows the extractor to jump over the rim of the cartridge and the bolt carrier continues rearward, grabbing the next round and causing the classic "fired case in chamber, live round behind it" FTE.

The brass shavings under the extractor usually contribute to this one as well.

#2 The extractor does NOT slip off the case, but keeps pulling.

The extractor is strong enough to RIP the rim right off the case.

Same result as above, but MORE brass shavings everywhere from ripping case rims off.

#3 The extractor does NOT slip off the case, but keeps pulling.

During this pulling, the bullet has JUST left the bore, pressures recede and the case shrinks down, allowing extraction.

The rest of the cycle goes as normal, but you have strong pull marks on the case.

Recoil will be higher than normal when the carrier is allowed to travel to the end of the buffer tube and bottom out swiftly against the end of the buffer tube.

In normal operation, the buffer just kisses the end of the tube.

Somewhere between here and the next section, we have proper operation.

Lastly, not enough gas(less common):

The bullet is out of the bore, pressure is subsided, case is extracted and on it's way to ejection.

Depending on the severity of the lack of gas, the bolt carrier may not even get the case out of the chamber before the operating spring returns it forward.

Adding more gas, the case just barely gets out of the ejection port, but the bolt grabs it on it's way forward, classic stovepipe.

Add more gas and the cartridge clears the action, but the bolt does NOT get far enough back to strip a round from the mag.

This is classic short stroking.

You have a single shot action which extracts and ejects, then closes on an empty chamber after you fire it.

In this condition, the bolt will also ride over an empty magazine and close on an empty chamber.

Add some more gas and you will reach the point where it feeds from the magazine and ALMOST works properly, but it still closes over an empty mag.

This is two things, first, poor mag springs are not pushing the follower up fast enough to catch the bolt and second, the bolt is not quite making it back far enough to catch on the magazine follower.

Add just a little more gas and you are back to proper function.

Now, take note, that a lack of gas in a rifle that was functioning fine before can be from several things:

Gas key screws poorly staked and they loosened up, allowing some gas to escape instead of doing it's job INSIDE the bolt carrier.

Gas ring gaps are aligned, gas rings missing or broken, allowing extra gas to flow past them.

Gas block/front sight base is loose, allowing gas to escape before it even gets down the gas tube.

Gas tube "mushroom" is severly worn, probably because it was not properly aligned with the gas key and gas is escaping there.

Here is a picture of a worn out gas tube mushroom:

Please note that failure to extract/eject is a symptom of EITHER too much or too little function of the action.

FTE alone is not enough information to decide what to change to fix the problem.

You need to look for other signs such as the excessive recoil and case rim pulling of too much gas or the short stroking of too little gas.

Unfortunately, many guys who don't understand the magic above always ASSUME that they have too little gas.

What do they do?

They open up the gas port.

Following the examples above, you can see this only makes the problem worse.

Whew, that was longer than I expected to write.

Hope it all sinks in and you can benefit from it.

Edited 2-3-06 to add more about gas port pressures:

We often hear about mid-length being smoother cycling or pistol being harsher cycling than the typical carbine length gas systems.

Below is a plot of a 223 load.

I have noted the locations of the various gas ports in blue.

You can plainly see what pressures are introduced into the gas systems when the bullet JUST passes the gas port.

This is the reason for the way the various gas system lengths function differently.

The longer the gas system from the chamber, the smoother the gun runs, allowing for the fastest double-taps without the gun jumping off target.

Projectile travel at the bottom assumes that the bullet starts out about 1.5" from the breech, so add 1.5" if you want to compare velocities at different lengths.

Edited 4-8-07 to add more about gas system dwell time:

There has been a lot of discussion lately about dwell time and how it relates to the function of certain barrels, particularly 18" rifle-gassed, 18" mid-length and 14.5" mid-lengths.

I put together a new graphic to illustrate DWELL TIME.

To use this graphic, find the gas port location above the pressure trace (Orange marks) and then locate the barrel lengths below the pressure trace (Blue marks).

The DWELL TIME is the time between these two marks (indicated on the X axis of the graphic as well as in the data below the graphic.

Optimum dwell time is right around 0.200 ms when you use the two most common gas system/barrel length configurations of 20" rifles and 14.5" carbines.

|